Fill in a Valid Welder Performance Qualification Record Form

Document Sample

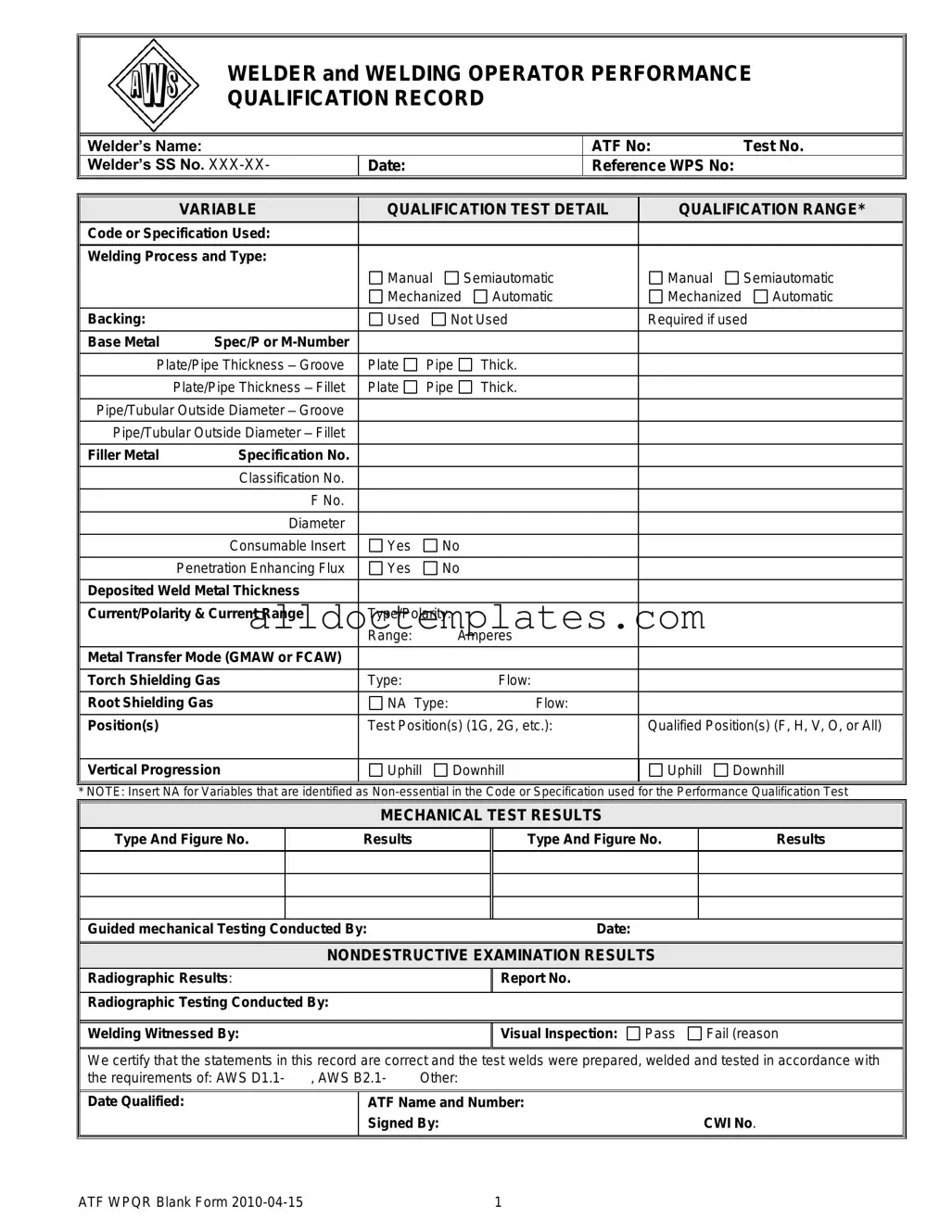

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||

Document Information

| Fact Name | Description |

|---|---|

| Welder Identification | The form requires the welder’s name, ATF number, and Social Security number for proper identification and record-keeping. |

| Qualification Test Details | It includes specific details about the qualification test, such as the welding process, backing used, and base metal specifications. |

| Welding Process Options | Welders can qualify under various processes: manual, semiautomatic, mechanized, and automatic, allowing flexibility in skill assessment. |

| Position Qualification | Test positions are specified (1G, 2G, etc.), and the qualified positions indicate the welder's capabilities in different orientations. |

| Mechanical Testing | Guided mechanical tests are documented, ensuring that the welder’s skills meet industry standards for strength and durability. |

| Non-Destructive Examination | Results from radiographic testing and visual inspections are recorded, providing assurance of weld integrity without damaging the welds. |

| Certification Statement | The form includes a certification statement confirming that all test welds were conducted according to specified codes, ensuring compliance. |

| Governing Codes | Commonly referenced codes include AWS D1.1 and AWS B2.1, which set the standards for welding qualifications across various states. |

| Signature Requirement | A signature from a Certified Welding Inspector (CWI) is required to validate the record, ensuring accountability and accuracy in reporting. |

Welder Performance Qualification Record - Usage Guidelines

Completing the Welder Performance Qualification Record form is an important step in documenting a welder's qualifications. This process ensures that all necessary information is accurately captured, which can help in verifying skills and compliance with industry standards. Follow these steps carefully to fill out the form correctly.

- Begin by entering the Welder’s Name at the top of the form.

- Fill in the ATF No and Test No in the designated spaces.

- Provide the Welder’s SS No (Social Security Number) in the appropriate section.

- Enter the Date of the test.

- Write the Reference WPS No (Welding Procedure Specification Number).

- Specify the Code or Specification Used for the qualification.

- Select the Welding Process and Type from the options provided (Manual, Semiautomatic, Mechanized, Automatic).

- Indicate whether a Backing was used or not.

- Provide the Base Metal Spec/P or M-Number.

- Fill in the Plate/Pipe Thickness for both Groove and Fillet welds.

- Specify the Pipe/Tubular Outside Diameter for both Groove and Fillet welds.

- Enter the Filler Metal Specification No and Classification No.

- Indicate the F No and Diameter of the filler metal.

- Specify if a Consumable Insert was used.

- Indicate if PENETRATION ENHANCING FLUX was used.

- Fill in the Deposited Weld Metal Thickness.

- Provide the Current/Polarity & Current Range including the type and range in Amperes.

- Indicate the Metal Transfer Mode (GMAW or FCAW).

- Specify the Torch Shielding Gas Type and Flow.

- Indicate the Root Shielding Gas type and flow, if applicable.

- Fill in the Test Position(s) and Qualified Position(s).

- Specify the Vertical Progression (Uphill or Downhill).

- In the MECHANICAL TEST RESULTS section, enter the type and figure number of the tests conducted, along with the results.

- Provide the name of the Guided Mechanical Testing Conducted By and the Date.

- In the NONDESTRUCTIVE EXAMINATION RESULTS section, fill in the Radiographic Results and Report No.

- Specify who conducted the Radiographic Testing and who witnessed the welding.

- Complete the Visual Inspection section by indicating whether the result was a Pass or Fail, and provide a reason if it was a Fail.

- Certify the statements in the record by entering the Date Qualified, ATF Name and Number, and the Signed By section.

- Finally, enter the CWI No (Certified Welding Inspector Number).

Common PDF Forms

Military Awards After Discharge - Veterans can use the DD 149 to dispute inaccuracies in their service records.

For those looking to navigate the complexities of transferring ownership, it's important to have the proper documentation, such as the Utah Mobile Home Bill of Sale, which can be found at mobilehomebillofsale.com/blank-utah-mobile-home-bill-of-sale, ensuring that all parties are protected during the transaction.

State Disability California - Timely submission of the DE 2501 can result in faster receipt of disability benefits.

Dos and Don'ts

When filling out the Welder Performance Qualification Record form, it is important to follow certain guidelines to ensure accuracy and compliance. Here are six things to do and avoid:

- Do fill in all required fields completely. Missing information can lead to delays or disqualification.

- Do double-check the reference WPS number for accuracy. This ensures the qualification aligns with the correct welding procedure.

- Do use clear and legible handwriting or type the information. Clarity helps prevent misunderstandings.

- Do ensure that all signatures are obtained where required. This includes signatures from the welder, inspector, and any other relevant parties.

- Don't leave any essential fields blank. If a variable is not applicable, write "NA" as instructed.

- Don't forget to keep a copy of the completed form for your records. This can be crucial for future reference or audits.

Common mistakes

-

Incomplete Personal Information: One common mistake is failing to provide complete personal details. This includes the welder's name, ATF number, and Social Security number. Missing any of these can lead to delays in processing the qualification.

-

Incorrect or Missing WPS Reference: The Welding Procedure Specification (WPS) reference is crucial for validating the qualifications. If this field is left blank or contains incorrect information, it can invalidate the entire record.

-

Neglecting to Specify Test Variables: When filling out the qualification range, it's important to accurately indicate whether variables such as backing, base metal specifications, and filler metal classifications were used. Omitting this information can lead to confusion about the welder's capabilities.

-

Failure to Document Test Results: After conducting mechanical tests and non-destructive examinations, results must be documented clearly. Failing to include these results or providing incomplete data can raise questions about the integrity of the qualification.