Fill in a Valid Dot Vehicle Inspection Form

Document Sample

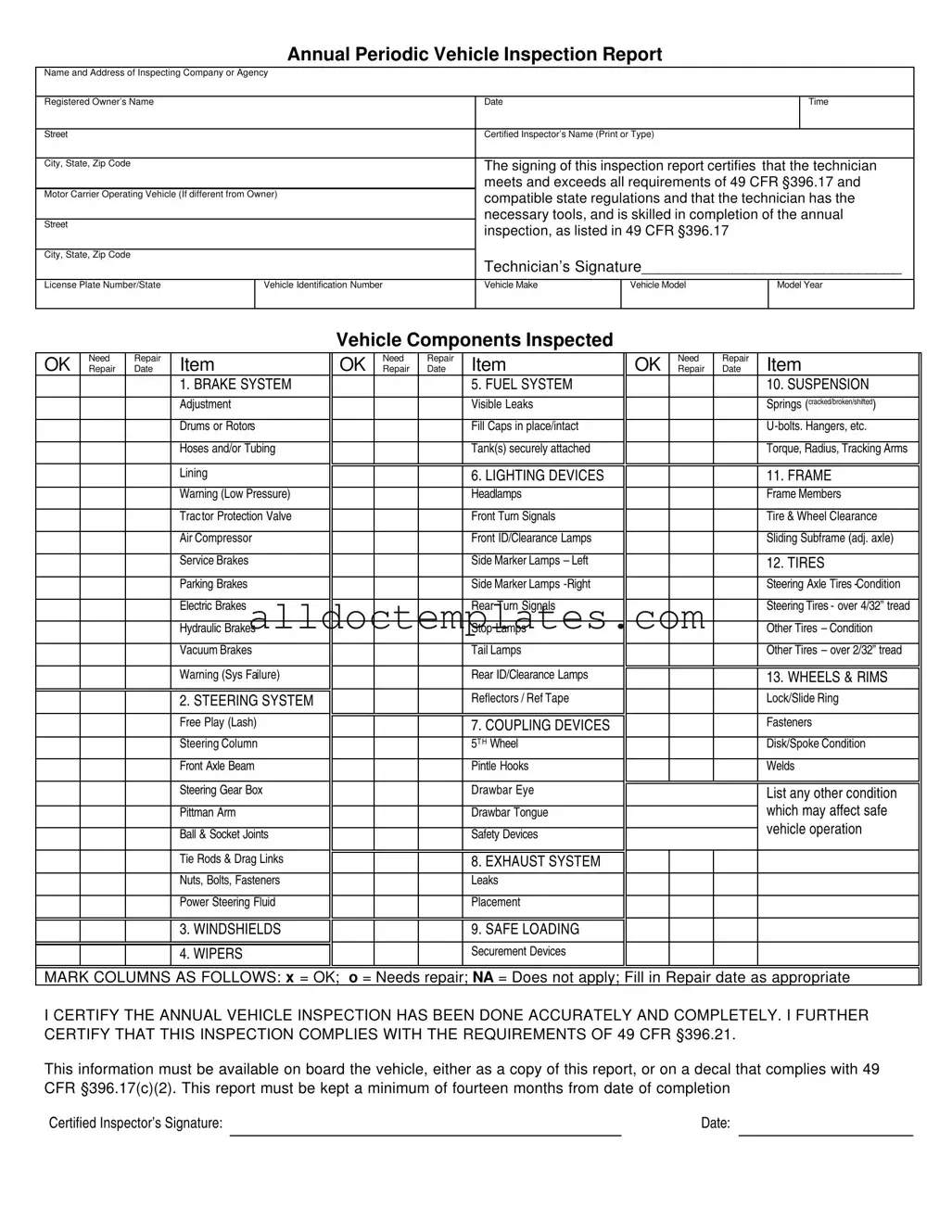

Annual Periodic Vehicle Inspection Report

Name and Address of Inspecting Company or Agency

Registered Owner’s Name |

|

Date |

|

|

Time |

|

|

|

|

|

|

Street |

|

Certified Inspector’s Name (Print or Type) |

|

|

|

|

|

|

|

|

|

City, State, Zip Code |

|

The signing of this inspection report certifies that the technician |

|||

|

|

meets and exceeds all requirements of 49 CFR §396.17 and |

|||

Motor Carrier Operating Vehicle (If different from Owner) |

compatible state regulations and that the technician has the |

||||

|

|

||||

|

|

necessary tools, and is skilled in completion of the annual |

|||

Street |

|

inspection, as listed in 49 CFR §396.17 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

City, State, Zip Code |

|

|

|

|

|

|

|

Technician’s Signature______________________________ |

|||

|

|

|

|

|

|

License Plate Number/State |

Vehicle Identification Number |

Vehicle Make |

Vehicle Model |

Model Year |

|

|

|

|

|

|

|

Vehicle Components Inspected

OK |

Need |

Repair |

Item |

OK |

Need |

Repair |

Item |

OK |

Need |

Repair |

Item |

|

Repair |

Date |

Repair |

Date |

Repair |

Date |

|

||||||

|

|

|

1. BRAKE SYSTEM |

|

|

|

5. FUEL SYSTEM |

|

|

|

10. SUSPENSION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjustment |

|

|

|

Visible Leaks |

|

|

|

Springs (cracked/broken/shifted) |

|

|

|

|

Drums or Rotors |

|

|

|

Fill Caps in place/intact |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hoses and/or Tubing |

|

|

|

Tank(s) securely attached |

|

|

|

Torque, Radius, Tracking Arms |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lining |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. LIGHTING DEVICES |

|

|

|

11. FRAME |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning (Low Pressure) |

|

|

|

Headlamps |

|

|

|

Frame Members |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tractor Protection Valve |

|

|

|

Front Turn Signals |

|

|

|

Tire & Wheel Clearance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air Compressor |

|

|

|

Front ID/Clearance Lamps |

|

|

|

Sliding Subframe (adj. axle) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Service Brakes |

|

|

|

Side Marker Lamps – Left |

|

|

|

12. TIRES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parking Brakes |

|

|

|

Side Marker Lamps |

|

|

|

Steering Axle Tires |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric Brakes |

|

|

|

Rear Turn Signals |

|

|

|

Steering Tires - over 4/32” tread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hydraulic Brakes |

|

|

|

Stop Lamps |

|

|

|

Other Tires – Condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum Brakes |

|

|

|

Tail Lamps |

|

|

|

Other Tires – over 2/32” tread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning (Sys Failure) |

|

|

|

Rear ID/Clearance Lamps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13. WHEELS & RIMS |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reflectors / Ref Tape |

|

|

|

Lock/Slide Ring |

|

|

|

|

2. STEERING SYSTEM |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Free Play (Lash) |

|

|

|

|

|

|

|

Fasteners |

|

|

|

|

|

|

|

7. COUPLING DEVICES |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering Column |

|

|

|

5T H Wheel |

|

|

|

Disk/Spoke Condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Front Axle Beam |

|

|

|

Pintle Hooks |

|

|

|

Welds |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steering Gear Box |

|

|

|

Drawbar Eye |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

List any other condition |

|

||

|

|

|

|

|

|

|

|

|

|

|

which may affect safe |

|

|

|

|

Pittman Arm |

|

|

|

Drawbar Tongue |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

vehicle operation |

|

|

|

|

Ball & Socket Joints |

|

|

|

Safety Devices |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tie Rods & Drag Links |

|

|

|

8. EXHAUST SYSTEM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nuts, Bolts, Fasteners |

|

|

|

Leaks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Steering Fluid |

|

|

|

Placement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. WINDSHIELDS |

|

|

|

9. SAFE LOADING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Securement Devices |

|

|

|

|

|

|

|

|

4. WIPERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MARK COLUMNS AS FOLLOWS: x = OK; o = Needs repair; NA = Does not apply; Fill in Repair date as appropriate

I CERTIFY THE ANNUAL VEHICLE INSPECTION HAS BEEN DONE ACCURATELY AND COMPLETELY. I FURTHER CERTIFY THAT THIS INSPECTION COMPLIES WITH THE REQUIREMENTS OF 49 CFR §396.21.

This information must be available on board the vehicle, either as a copy of this report, or on a decal that complies with 49 CFR §396.17(c)(2). This report must be kept a minimum of fourteen months from date of completion

Certified Inspector’s Signature: |

|

Date: |

|

|

|

INSPECTOR QUALIFICATIONS

Certification — 49 CFR §396.19

Motor carriers are responsible for ensuring that individual(s) performing an annual inspection under §396.17 are qualified as follows:

•Understands the inspection criteria set forth in Part 393 and Appendix G and can identify defective components

•Is knowledgeable of and has mastered the methods, procedures, tools and equipment used when performing an inspection

•Is capable of performing an inspection by reason of experience, training, or both, and qualifies in one of the following categories (check all that apply):

I.___ Successfully completed a State or Federal training program or has certificate from a State or Canadian Province which qualifies the person to perform commercial vehicle safety inspections.

Specify: _______________________________________

II.___ Have a combination of training or experience totaling at least one year as follows (check all that apply):

a.___ Participation in a truck

Where and Date: _____________________________________________________

b.___ (years) experience as a mechanic or inspector in a motor carrier maintenance program.

Name and Date: _____________________________________________________

c.___ (years) experience as a mechanic or inspector in truck maintenance at a commercial garage, fleet leasing company, or similar facility.

Name of Facility and Dates: ____________________________________________

d.___ (years) experience as a commercial vehicle inspector for a State, Provincial, or Federal Government.

Where and Dates: ____________________________________________________

I certify the above information is true and accurate to the best of my knowledge.

Employee ______________________________________ |

________________ |

Signature of Mechanic/Inspector |

Date |

Motor Carrier/Company ____________________________________ |

________________ |

Signature of Employer/Supervisor |

Date |

Evidence of Inspector Qualification is on file at:

_______________________________

BRAKE INSPECTOR QUALIFICATIONS

Certification — 49 CPR §396.25

“Brake Inspector” means any employee of a motor carrier who is responsible for ensuring all brake inspections, maintenance, service, or repairs to any commercial motor vehicle, subject to the motor carrier’s control, meet the applicable Federal standards.

No motor carrier shall require or permit any employee who does not meet minimum brake inspector qualifications to be responsible for the inspection, maintenance, service or repairs of any brakes on its commercial motor vehicles.

Minimum Qualifications

•Understands and can perform brake service and inspection

•Is knowledgeable of and has mastered the methods, procedures, tools and equipment necessary to perform brake service and inspection

•Is capable of performing brake service or inspection by reason of experience, training, or both, and qualifies in one of the following categories (check all that apply):

I.___Has successfully completed an apprenticeship program sponsored or approved

by a State, Canadian Province, a Federal agency or labor union, or has a certificate from a State or Canadian Province which qualifies the person to perform brake service or inspections.

Specify: ________________________________________________________________

II.___ Has

a.___Participation in a brake maintenance or inspection training program sponsored by a brake or vehicle manufacturer or similar commercial training program.

Where and Date:_______________________________________________

b.___ (years) experience performing brake maintenance or inspection in a motor carrier maintenance program.

Name and Date:_______________________________________________

c.___ (years) experience performing brake maintenance or inspection at a commercial garage, fleet leasing company, or similar facility.

Name of Facility and Dates:______________________________________

I certify the above information is true and accurate to the best of my knowledge.

Employee ______________________________________ |

________________ |

Signature of Mechanic/Inspector |

Date |

Motor Carrier/Company ____________________________________ |

________________ |

Signature of Employer/Supervisor |

Date |

Evidence of Inspector Qualification is on file at:

_______________________________

Document Information

| Fact Name | Description |

|---|---|

| Purpose of the Form | The DOT Vehicle Inspection form is used to document the results of an annual vehicle inspection, ensuring compliance with federal and state regulations. |

| Governing Laws | This form adheres to the requirements outlined in 49 CFR §396.17 and other compatible state regulations, which govern vehicle inspections. |

| Inspector Qualifications | Inspectors must meet specific qualifications, including understanding inspection criteria and having relevant training or experience, as per 49 CFR §396.19. |

| Inspection Components | The form includes sections for various vehicle components, such as brakes, tires, and lighting, which must be inspected for safety and functionality. |

| Repair Documentation | Any items needing repair must be clearly marked, and repair dates must be documented to ensure accountability and follow-up. |

| Record Keeping | Inspection reports must be kept for a minimum of fourteen months from the date of completion, either on board the vehicle or as a compliant decal. |

| Certification Requirement | The form requires signatures from both the certified inspector and the mechanic, certifying that the inspection was performed accurately and completely. |

Dot Vehicle Inspection - Usage Guidelines

Completing the DOT Vehicle Inspection form is essential for ensuring that your vehicle meets safety standards. Follow the steps below to fill out the form accurately. Ensure all information is correct and legible, as this report is a legal document that may be required during inspections or audits.

- Enter the Name and Address of the inspecting company or agency at the top of the form.

- Fill in the Registered Owner’s Name.

- Write the Date and Time of the inspection.

- Provide the Street, City, State, Zip Code of the registered owner.

- Print or type the Certified Inspector’s Name.

- Complete the Motor Carrier Operating Vehicle section if it differs from the owner.

- List the License Plate Number/State and Vehicle Identification Number.

- Specify the Vehicle Make, Vehicle Model, and Model Year.

- Inspect the vehicle components listed and mark each item as follows: x for OK, o for Needs repair, and NA for Does not apply.

- For any items that need repair, fill in the Repair Date.

- Certify the inspection by signing the form in the Technician’s Signature section.

- Complete the Inspector Qualifications section, checking all applicable qualifications.

- Sign and date the Certified Inspector’s Signature section.

Once the form is filled out, keep a copy on board the vehicle or display it as a decal, as required by federal regulations. Retain this report for at least fourteen months from the completion date to ensure compliance with safety standards.

Common PDF Forms

Transfer Tax Nj - The affidavit affects both residential and commercial property sales.

Aaa International License - Make sure to specify if you need assistance in filling out the form.

A Colorado Durable Power of Attorney form is a legal document that allows you to appoint someone to make decisions on your behalf if you become unable to do so. This trusted individual, known as your agent, can handle various matters, including financial and healthcare decisions. For more information and to access a template, you can visit Colorado PDF Templates. Understanding how this form works is essential for ensuring your wishes are respected during challenging times.

Qdro Divorce Form - Each assignment method is distinctly outlined to ensure proper compliance.

Dos and Don'ts

When filling out the DOT Vehicle Inspection form, it is essential to adhere to specific guidelines to ensure accuracy and compliance. Below is a list of things you should and shouldn't do during this process.

- Do ensure all required fields are filled out completely, including the names of the inspecting company and registered owner.

- Do use clear and legible handwriting or type the information to avoid any misinterpretation.

- Do mark the condition of each vehicle component accurately using the designated symbols (x for OK, o for needs repair, NA for not applicable).

- Do include the repair dates for any components that need attention to maintain a clear record.

- Do keep a copy of the completed inspection report on board the vehicle as required by regulations.

- Don't leave any sections blank; incomplete forms may lead to compliance issues or penalties.

- Don't use abbreviations or unclear terms that could confuse the reader or inspector.

- Don't forget to sign and date the form to certify that the inspection has been completed accurately.

- Don't ignore the qualifications of the inspector; ensure they meet the necessary standards outlined in the regulations.

- Don't submit the form without double-checking for errors or omissions.

Common mistakes

-

Inaccurate Information: Failing to provide correct details such as the name of the inspecting company or the registered owner's name can lead to significant issues. It is crucial that all information is accurate to avoid confusion or legal problems.

-

Missing Signatures: The technician’s signature is essential for certifying the inspection. Omitting this signature can render the report invalid.

-

Neglecting Repair Dates: Not filling in the repair dates for items that need attention can create a lack of accountability. This oversight may result in unresolved issues that could affect vehicle safety.

-

Improper Marking of Conditions: Incorrectly marking the condition of vehicle components (e.g., using "NA" for items that do apply) can lead to misunderstandings about the vehicle's status. Each item should be marked accurately to reflect its condition.

-

Failure to List Additional Conditions: Not listing any other conditions that could affect safe vehicle operation can be a critical mistake. This information is vital for ensuring the vehicle is safe for use.

-

Ignoring Inspector Qualifications: The form requires the inspector to certify their qualifications. Failing to do so can lead to questions about the validity of the inspection. It is important to ensure that all qualifications are documented.

-

Retention of the Report: Not keeping a copy of the inspection report on board the vehicle, or failing to retain it for the required fourteen months, can lead to compliance issues. This document is essential for regulatory purposes.