Fill in a Valid Da 5988 E Form

Document Sample

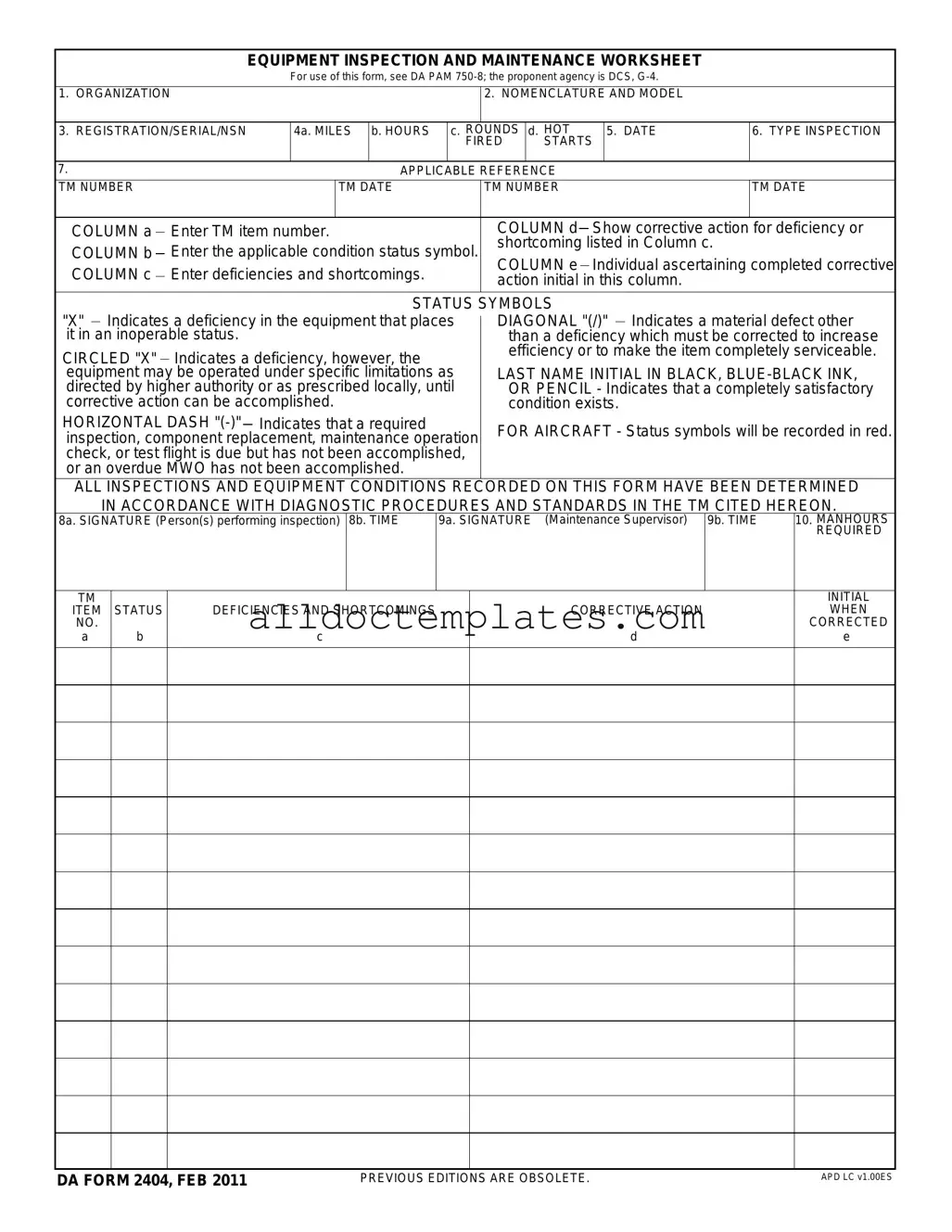

EQUIPMENT INSPECTION AND MAINTENANCE WORKSHEET

For use of this form, see DA PAM

|

1. ORGANIZATION |

|

|

|

|

|

2. NOMENCLATURE AND MODEL |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. REGISTRATION/SERIAL/NSN |

4a. MILES |

b. HOURS |

c. FIREDROUNDS |

d. STARTSHOT |

5. DATE |

6. TYPE INSPECTION |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. |

|

|

|

|

|

|

|

|

|

APPLICABLE REFERENCE |

|

|

|

|

||||||||

|

TM NUMBER |

|

|

TM DATE |

TM NUMBER |

|

|

|

TM DATE |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

COLUMN a |

|

Enter TM item number. |

COLUMN d |

|

Show corrective action for deficiency or |

||||||||||||||||

|

|

|||||||||||||||||||||

|

|

|

|

|||||||||||||||||||

|

COLUMN b |

|

|

|

|

Enter the applicable condition status symbol. |

shortcoming listed in Column c. |

|

||||||||||||||

|

|

|

COLUMN e |

|

|

Individual ascertaining completed corrective |

||||||||||||||||

|

COLUMN c |

|

|

Enter deficiencies and shortcomings. |

|

|

||||||||||||||||

|

|

|

|

|

||||||||||||||||||

|

|

action initial in this column. |

|

|||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

STATUS SYMBOLS |

|

|

|

|

|||||||

|

"X" |

|

Indicates a deficiency in the equipment that places |

DIAGONAL "(/)" |

|

Indicates a material defect other |

||||||||||||||||

|

|

|

||||||||||||||||||||

|

it in an inoperable status. |

|

|

|

|

than a deficiency which must be corrected to increase |

||||||||||||||||

|

CIRCLED "X" |

|

|

|

Indicates a deficiency, however, the |

efficiency or to make the item completely serviceable. |

||||||||||||||||

|

|

|

||||||||||||||||||||

|

equipment may be operated under specific limitations as |

LAST NAME INITIAL IN BLACK, |

||||||||||||||||||||

|

directed by higher authority or as prescribed locally, until |

OR PENCIL - Indicates that a completely satisfactory |

||||||||||||||||||||

|

corrective action can be accomplished. |

condition exists. |

|

|||||||||||||||||||

HORIZONTAL DASH

ALL INSPECTIONS AND EQUIPMENT CONDITIONS RECORDED ON THIS FORM HAVE BEEN DETERMINED IN ACCORDANCE WITH DIAGNOSTIC PROCEDURES AND STANDARDS IN THE TM CITED HEREON.

8a. SIGNATURE (Person(s) performing inspection) 8b. TIME 9a. SIGNATURE (Maintenance Supervisor) 9b. TIME 10. MANHOURS REQUIRED

TM |

|

|

|

INITIAL |

ITEM |

STATUS |

DEFICIENCIES AND SHORTCOMINGS |

CORRECTIVE ACTION |

WHEN |

NO. |

|

|

|

CORRECTED |

a |

b |

c |

d |

e |

DA FORM 2404, FEB 2011 |

PREVIOUS EDITIONS ARE OBSOLETE. |

APD LC v1.00ES |

|

|

TM |

STATUS |

ITEM |

|

NO. |

b |

a |

DEFICIENCIES AND SHORTCOMINGS

c

CORRECTIVE ACTION

d

INITIAL

WHEN

CORRECTED e

DA FORM 2404, FEB 2011

APD LC v1.00ES

Document Information

| Fact Name | Detail |

|---|---|

| Purpose | The DA 5988 E form is used for aircraft equipment inspection and maintenance tracking. |

| Status Symbols | Status symbols are recorded in red to indicate the condition of the equipment. |

| Inspection Types | The form allows for various types of inspections to be documented. |

| Applicable References | References to technical manuals (TM) are required for proper documentation. |

| Signature Requirements | Signatures from both the person performing the inspection and the maintenance supervisor are necessary. |

| Condition Status Symbols | Symbols such as "X" and "(/)" indicate different levels of equipment deficiencies. |

| Documentation of Deficiencies | Deficiencies and shortcomings must be clearly documented in the appropriate columns. |

| Corrective Actions | Corrective actions for deficiencies must be noted and initialed upon completion. |

| Manhours Tracking | The form includes a section for recording the manhours required for maintenance tasks. |

| Regulatory Guidance | The DA 5988 E form follows guidelines set forth in DA PAM 750-8. |

Da 5988 E - Usage Guidelines

Filling out the DA 5988 E form is an essential step in documenting equipment inspection and maintenance. This form helps ensure that all necessary information is recorded accurately for proper equipment management. Follow the steps below to complete the form effectively.

- Organization: Write the name of your organization in the first box.

- Nomenclature and Model: Enter the specific name and model of the equipment being inspected.

- Registration/Serial/NSN: Fill in the registration number, serial number, or National Stock Number (NSN) of the equipment.

- Miles, Hours, Fired Rounds, Start Shot:

- In the 'Miles' box, enter the mileage if applicable.

- In the 'Hours' box, input the total operating hours.

- For 'Fired Rounds,' list the number of rounds fired.

- In 'Start Shot,' record the initial shot count if relevant.

- Date: Write the date of the inspection.

- Type Inspection: Specify the type of inspection being conducted.

- Applicable Reference TM Number: Enter the Technical Manual (TM) number associated with the inspection.

- TM Date: Fill in the date of the TM.

- Deficiencies and Shortcomings:

- In Column a, enter the TM item number.

- In Column b, provide the applicable condition status symbol.

- In Column c, list any deficiencies and shortcomings.

- In Column d, show the corrective action taken for each deficiency.

- In Column e, have the individual who completed the corrective action initial this column.

- Signatures:

- In 8a, the person performing the inspection should sign.

- In 8b, record the time of the inspection.

- In 9a, the maintenance supervisor should sign.

- In 9b, note the time of the supervisor’s signature.

- Manhours Required: Indicate the total manhours required for the inspection and maintenance.

After completing the form, ensure that all sections are filled out clearly and accurately. This will help maintain proper records and facilitate any necessary follow-up actions regarding the equipment.

Common PDF Forms

Status Change Form - Utilize this form for tracking any changes that affect employee job security.

For individuals looking to understand and utilize property transfer methods, a useful resource on how to manage a Quitclaim Deed effectively can be found at this guide to completing a Quitclaim Deed.

Revocable Trust Amendment Form - This form ensures compliance with your state’s contract law regarding living trusts.

Dos and Don'ts

When filling out the DA 5988 E form, attention to detail is crucial. Here are some important dos and don'ts to keep in mind:

- Do use black or blue-black ink when signing the form. This ensures clarity and professionalism.

- Do accurately enter all required information in the specified columns. Each section has a purpose, and completeness is key.

- Do clearly indicate deficiencies and shortcomings in Column c. This helps in addressing issues promptly.

- Do have the individual performing the inspection initial the corrective actions in Column e. This adds accountability.

- Don't use pencil for signatures or important entries. It can smudge or fade over time, leading to confusion.

- Don't leave any columns blank unless instructed. Missing information can delay maintenance and inspections.

Common mistakes

-

Neglecting to use the correct ink color: Individuals often forget that the form requires signatures to be in black, blue-black ink, or pencil. Using any other color can lead to issues with the document's validity.

-

Omitting essential information: Each section of the form is crucial. Failing to fill out any of the required fields, such as the organization name or the registration number, can result in delays or complications in processing.

-

Incorrectly marking status symbols: Misunderstanding the status symbols can lead to serious errors. For instance, marking a deficiency as an "X" when it should be a circled "X" can misrepresent the equipment's operability.

-

Inaccurate date entry: Entering the wrong date can create confusion regarding inspection timelines. It is essential to ensure that the date reflects the actual inspection or maintenance performed.

-

Failure to initial corrective actions: After completing a corrective action, the individual must initial the appropriate column. Skipping this step can leave the form incomplete and may hinder the tracking of maintenance history.

-

Misidentifying deficiencies and shortcomings: It is vital to accurately describe any deficiencies. Vague or incorrect descriptions can lead to misunderstandings about what repairs are necessary.

-

Not recording manhours accurately: When documenting manhours required for maintenance, precision is key. Inaccurate entries can affect resource allocation and planning for future inspections.

-

Overlooking the review process: Before submitting the form, it is important to review all entries for accuracy. Failing to do so can result in overlooked mistakes that may complicate maintenance procedures.